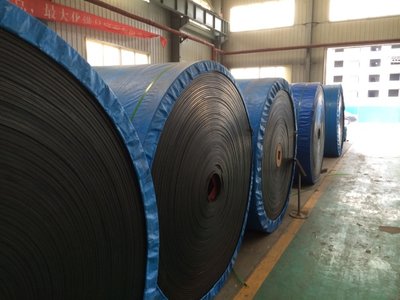

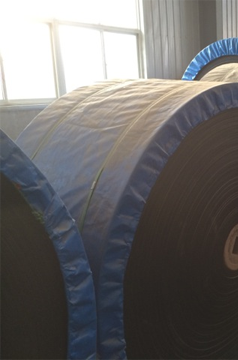

Reinforced Rubber Conveyor Belts

D.E.N. Technologies Corporation attaches particular importance to the horizontal conveying of goods. We offer numerous conveying solutions and manufacture reinforced rubber conveyor belts of superior quality for a variety of applications. Optimized manufacturing processes and state-of-the-art equipment ensure great quality of our products. We are committed to providing you with quality products.

We offer competent advice, a complete package of services and customized support. We strive to provide excellent customer service.

Reinforced Rubber Conveyor Belt Options

Rubber Covers (in Compliance with DIN 22102):

Х- Multi-ply conveyor belts for abrasive materials and sharp-edged large lumps;

W- Multi-ply conveyor belts for highly abrasive granular and bulk materials;

Y- Multi-ply conveyor belts for abrasive and sharp-edged small sized bulk materials;

T- Multi-ply conveyor belts for lump bulk materials at high temperature conditions. At out D.E.N. Technologies manufacturing facility, we can produce conveyor belts resistant to the temperature of up to +400°C (momentary peak temperature of 450 °C);

R– Cold-resistant multi-ply conveyor belts designed to operate in a range of temperatures from - 60 to +60 °C.

Carcass Material:

ЕР - polyester threads in multi-ply conveyor belts ensure high tensile strength with low elongation (no more than 2%);

Nylon weft makes our multi-ply conveyor belts shock resistant and flexible.

Standard Width:

300, 400, 500, 600, 650, 800, 1000, 1200, 1300, 1400, 1600, 1800, 2000, 2200, 2400 mm<

Reinforced multi-ply conveyor belts of other widths can be manufactured at customer’s request.

Tensile Strength:

Reinforced multi-ply conveyor belts have a tensile strength of ЕР 250 N/mm to ЕР 3150 N/mm.

Designation example:

|

2000 |

EP |

1600 |

/5 |

10 |

/3 |

Y |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

where:

- - width;

- – fabric carcass type;

- - tensile strength, N/mm;

- – number of fabric plies;

- – thickness of the top rubber cover;

- - thickness of the bottom rubber cover;

- - rubber cover type.

Examples of Standard Types:

| Carcass Type | Rubber Cover Thickness | Thickness (mm) | |

| Top | Bottom | ||

| EP-250/2 | 2 | 0 | 4.0 |

| EP-250/2 | 2.5 | 1 | 6.0 |

| EP-250/2 | 4 | 2 | 8.0 |

| EP-315/2 | 3 | 1 | 6.2 |

| EP-315/3 | 4 | 2 | 9.0 |

| EP-400/3 | 2 | 0 | 6.6 |

| EP-400/3 | 4 | 2 | 9.0 |

| EP-400/4 | 3 | 1.5 | 9.5 |

| EP-500/3 | 5 | 2 | 10.0 |

| EP-500/4 | 6 | 2 | 12.0 |

| EP-500/4 | 3 | 1 | 7.0 |

| EP-630/4 | 4 | 2 | 10.0 |

| EP-800/4 | 5 | 2 | 13.0 |

| EP-1000/4 | 6 | 2 | 14.6 |

| EP-1250/4 | 8 | 2 | 17.6 |

| EP-1600/4 | 8 | 2 | 19.0 |

| EP-2000/5 | 8 | 2 | 21.3 |

| EP-2500/5 | 10 | 3 | 27.3 |

| EP-3150/5 | 10 | 3 | 29.8 |

Minimal Pulley Diameter:

| Tensile strength, N/mm |

Minimal pulley diameter, mm | ||||

| Number of fabric plies | |||||

| 2 | 3 | 4 | 5 | 6 | |

| 250 | 200 | ||||

| 400 | 300 | 400 | 500 | ||

| 500 | 350 | 450 | 550 | ||

| 630 | 500 | 600 | 700 | ||

| 800 | 600 | 700 | 750 | 850 | |

| 1000 | 700 | 800 | 850 | 950 | |

| 1250 | 900 | 1000 | 1050 | ||

| 1600 | 1000 | 1150 | 1300 | ||

| 2000 | 1400 | 1500 | |||

| 2500 | 1500 | 1650 | |||

| 3150 | 1600 | 1700 | |||

Tensile Strength, Carcass Structure and Number of Plies:

| Tensile strength, N/mm |

2 | 3 | 4 | 5 | 6 |

| 250 | 250/2 | ||||

| 400 | 400/2 | 400/3 | 400/4 | ||

| 500 | 500/2 | 500/3 | 500/4 | ||

| 630 | 630/3 | 630/4 | 630/5 | ||

| 800 | 800/3 | 800/4 | 800/5 | 800/6 | |

| 1000 | 1000/3 | 1000/4 | 1000/5 | 1000/6 | |

| 1250 | 1250/4 | 1250/5 | 1250/6 | ||

| 1600 | 1600/4 | 1600/5 | 1600/6 | ||

| 2000 | 2000/5 | 2000/6 | |||

| 2500 | 2500/5 | 2500/6 | |||

| 3150 | 3150/5 | 3150/6 |

Reinforced rubber conveyor belts can be manufactured with any combination of covers at customer’s request.

Customers can get reinforced rubber conveyor belts of any length, but a coil should weigh no more than 12 ton.

Reinforced rubber conveyor belts are fitted with a rubber sidewall.

Our products are covered by a minimum 12-month manufacturer’s warranty that applies in case of compliance with operational, transportation and storage requirements.

The purchased products can be delivered to customer’s warehouse.

Puncture-Resistant Reinforced Rubber Conveyor Belts

Specifications

Application:

Puncture-resistant reinforced rubber conveyor belts are widely used for conveying of goods at lumber factories, iron and steel plants, mines, quarries and glass factories.

Structural Features:

The carcass is made of ЕР polyester nylon fabric with a breaker between the rubber cover and the carcass.

Tensile Strength:

The tensile strength of puncture-resistant reinforced rubber conveyor belts is from ЕР 315 N/mm to ЕР 3150 N/mm.

Available Breaker Types:

RC– steel cord with increased longitudinal and lateral flexibility. Used for trough belt conveyors.

SC– steel cord reinforcement with increased longitudinal flexibility and lateral stiffness. Used for flat-base conveyors, cannot form a trough.

BR– flexible polyamide cord (for conveyors with metal detectors and magnetic separators).

Standard Width:

400, 500, 600, 650, 800, 1000, 1200, 1300, 1400, 1600, 1800, 2000 mm.

Puncture-resistant reinforced rubber conveyor belts of other widths can be manufactured at customer’s request.

| Width | Carcass | Rubber covers |

| 400,500, 650, 800, 1000, 1200 | EP500/ 3 + 1 RC | 5/2 Y |

Belt Designation Example

| 1200 | EP | 500 | /3 | +1 RC | 5 | /2 | Y |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

where:

- width;

- fabric carcass type;

- tensile strength, N/mm;

- number of fabric plies;

- thickness of the top rubber cover;

- thickness of the bottom rubber cover;

- rubber cover type.

- rubber cover type.