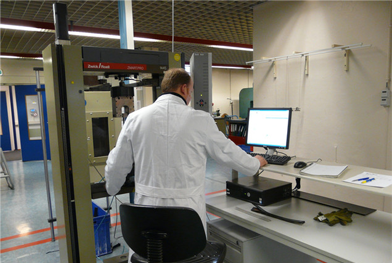

Our company is committed to use state-of- the art equipment and materials to ensure high quality and safety of our products. The primary goal of our Laboratory Testing Center is to enhance product performance through the improvement of technological processes and introduction of innovations and modern materials. The center is staffed with qualified experts in the fields of mechanical engineering, chemistry, polymers, and rubber and textile industry technologies.

Our manufacturing facility is ISO 9001:2000 certified. D.E.N. conveyor belts undergo regular tests to ensure compliance with the most stringent standards and regulations. Dynamic techniques used to test the product performance guarantee that every conveyor belt is fit for the intended use. Each belt undergoes comprehensive testing before it is shipped to the customer.

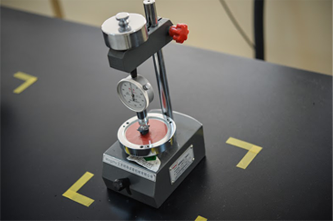

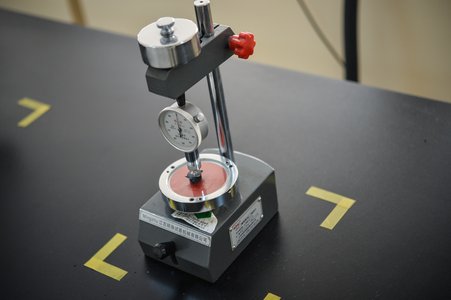

The testing program includes:

- Measuring

- Warp and weft tensile strength

- Rapture strength

- Stretching

- Adhesion of rubber cover to fabric carcass

- Small-scale safety testing (laboratory testing with open fire and electrical resistance testing)

- Abrasion resistance

- Lateral stability

- Resistance to high/low temperatures

- Resistance to oils and lubricants

- Custom testing

We make sure that each conveyor belt satisfies the requirements of our customers and is fit for its intended purpose. We also test if the belt can be spliced with metal fasteners or through hot pressing. Our manufacturing facility is equipped with a range of testing devices.